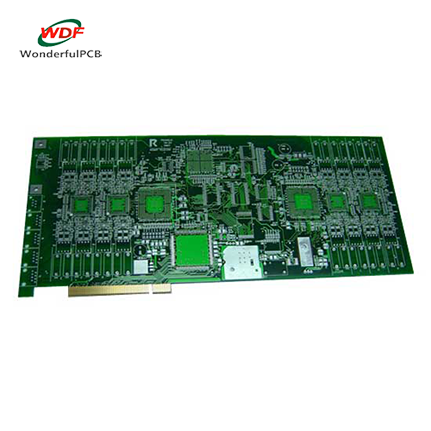

- Brand Name: Customized

- Min.Order Quantity:?No

- Supply Ability:?30~50 thousand ㎡/Month

- Port:?Shenzhen

- Service:?EMS/OEM/ODM

- Payment Terms:?T/T,Paypal,WU etc.

- Layer:?6

- Base Material:?Rogers + FR4

- Copper Thickness:?1oz

- Board Thickness:?2.3mm

- Solder Mask Color:?Green(can customized)

- Silkscreen Color:?White(can customized)

- Surface Finishing:?Immersion Gold

- Application Industry:?Communication

- Application Products:?Power amplifier

- Outer Line width/space:?7/7mil

PRODUCT DETAIL

This Printed Circuit Board is a Custom 6 Layers Rogers + FR4 Mix Stack Up PCB Circuit Board Manufacturing,used in Communication,some like Power amplifier,A PCB Circuit Board with Immersion Gold Surface Finishing is a coating between a component and a bare pcb circuit board,KingSong Tehnology as a professional PCB Manufacturer are not only offer Rogers pcb board,but also Ceramic pcb,FR-4 layer pcb or Multilayer pcb etc.

1.Detail?PCB Manufacturing?Capabilities:

| No. | Item | Mass Production | Prototype |

| 1 | Layers | 1-8 Layers | 1-36 Layers |

| 2 | Max. Panel Size | 600*770mm( 23.62″*30.31″) | 600*770mm(23.62″*30.31″) 500*1200mm(19.69″*47.24″) |

| 3 | Max.Board Thickness | 8.5mm | 8.5mm |

| 4 | Min. Board Thickness | 2L:0.3mm, 4L:0.4mm, 6L:0.8mm |

2L:0.2mm, 4L:0.4mm. 6L:0.6mm |

| 5 | Min Inner Layer Clearance | 0.1mm(4mil) | 0.1mm(4mil) |

| 6 | Min Line width | 0.075mm(3/3 mil) | 0.075mm(3/3 mil) |

| 7 | Min Line space | 0.075mm(3/3 mil) | 0.075mm(3/3 mil) |

| 8 | Min.Hole Size | 0.15mm(6mil) | 0.15mm(6mil) |

| 9 | Min plated hole thickness | 20um(0.8mil) | 20um(0.8mil) |

| 10 | Min Blind/Buried hole size | 0.1mm(4mil) | 0.1mm(1-8layers)(4mil) |

| 11 | PTH Dia. Tolerance | ±0.076mm(±3mil) | ±0.076mm(±3mil) |

| 12 | Non PTH Dia. Tolerance | ±0.05mm(±2mil) | ±0.05mm(±2mil) |

| 13 | Hole Position Deviation | ±0.05mm(±2mil) | ±0.05mm(±2mil) |

| 14 | Heavy Coppe | 4oz/140μm | 6oz/175μm |

| 15 | Min S/M Pitch | 0.1mm (4mil) | 0.1mm (4mil) |

| 16 | Soldermask colour | Green,black,Blue,White,Yellow,Red | Green,black,Blue,White,Yellow,Red |

| 17 | Silkscreen colour | White,Yellow,Red,Black | White,Yellow,Red,Black |

| 18 | Outline | Routing,V-Groove, Beveling punch | Routing,V-Groove, Beveling punch |

| 19 | Outline Tolerance | ±0.15mm ±6mil | ±0.15mm (±6mil) |

| 20 | Peelable mask | Top,bottom,double sided | Top,bottom,double sided |

| 21 | Controlled Impedance | +/- 10% | +/- 7% |

| 22 | Insulation Resistance | 1×1012Ω(Normal) | 1×1012Ω(Normal) |

| 23 | Through Hole Resistance | <300Ω(Normal) | <300Ω(Normal) |

| 24 | Thermal Shock | 3×10sec@288℃ | 3×10sec@288℃ |

| 25 | Warp and Twist | ≤0.7% | ≤0.7% |

| 26 | Electric Strength | >1.3KV/mm | >1.4KV/mm |

| 27 | Peel Strength | 1.4N/mm | 1.4N/mm |

| 28 | Solder Mask Abrasion | >6H | >6H |

| 29 | Flammability | 94V-0 | 94V-0 |

| 30 | Test Voltage | 50-330V | 50-330V |

2.PCB lead time:(if you need urgent service,we also can meet)

| Description | Double Layer | 4 Layer | 6 Layer | 8 Layer | 10 Layer or above |

| Sample(WD) | 3-5 | 7 | 8 | 10 | 12 |

| Mass production(WD) | 7-9 | 10-12 | 13-15 | 16 | 20 |

3.Package:Inner vacuum packing,Outer standard carton box packing.

4.Shipping:

A:By DHL,UPS,Fedex,TNT etc.

B:By sea for mass quantity according to customer’s requirement.

5.If need quotation for your PCB projects,pls provide following info:

A:Quote quantity,

B:Gerber file in 274-x format,

C:Technical requirement or parameters(material,layer,copper thickness,

board thickness,surface finishing,solder mask/silkscreen color…)

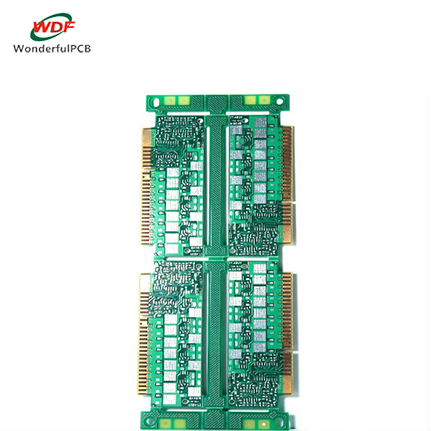

- Brand Name: Customized

- Min.Order Quantity:?No

- Supply Ability:?30~50 thousand ㎡/Month

- Port:?Shenzhen

- Service:?EMS/OEM/ODM

- Payment Terms:?T/T,Paypal,WU etc.

- Layer:?2

- Base Material:?FR4

- Copper Thickness:?1oz

- Board Thickness:?2.5mm

- Solder Mask Color:?Blue(can customized)

- Silkscreen Color:?White(can customized)

- White(can customized):?ENIG

PRODUCT DETAIL

LED PCB?Application:

1. Audio equipment: input, output amplifier, balanced amplifier, audio amplifier, preamplifier, power amplifier, etc.

2.Power equipment, switching regulator “DC/AC converter” SW regulator, etc.

3.Communication electronic equipment: high frequency increase ” filtering electrical” transmitting circuit.

4.Office automation equipment, motor drives, etc.

5.Automobile, electronic regulator “igniter” power controller, etc.

6.Computer: CPU board “diskette drive” power supply device, etc.

7.Power module, inverter “solid relay” rectifier bridge, etc.

2.PCB lead time:(if you need urgent service,we also can meet)

| Description | Single Layer | Double Layer |

| Sample(WD) | 3-5 | 5-7 |

| Mass production(WD) | 5-7 | 7-9 |

3.Package:Inner vacuum packing,Outer standard carton box packing.

4.Shipping:

A:By DHL,UPS,Fedex,TNT etc.

B:By sea for mass quantity according to customer’s requirement.

5.If need quotation for your PCB projects,pls provide following info:

A:Quote quantity,

B:Gerber file in 274-x format,

C:Technical requirement or parameters(material,layer,copper thickness,

board thickness,surface finishing,solder mask/silkscreen color…)

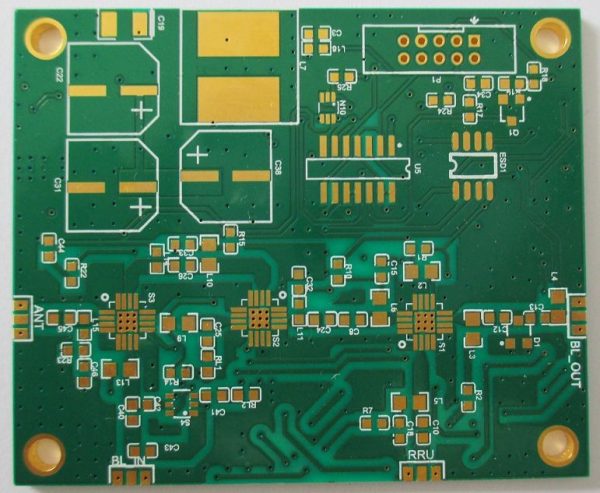

- Brand Name: Customized

- Min.Order Quantity:?No

- Supply Ability:?30~50 thousand ㎡/Month

- Port:?Shenzhen

- Service:?EMS/OEM/ODM

- Payment Terms:?T/T,Paypal,WU etc.

- Layer:?2

- Base Material:?polyimide

- Copper Thickness:?0.5oz

- Board Thickness:?0.25mm

- Solder Mask Color:?Black cover film

- Silkscreen Color:?White

- Surface Finishing:?OSP

- Test Way:?100% Test

- Standard:?IPC-Class2/Class 3

PRODUCT DETAIL

This?LED PCB?Board is a Manufacturing Black LED Light Bar Flexible PCB For Train,used for Lighting Production,A?LED PCB?Circuit Board with OSP Surface Finishing is a coating between a component and a bare led pcb circuit board,KingSong Tehnology as a professional LED PCB Manufacturer are not only offer Led Strip Pcb Suppliers,but also?Flexible Pcb For Led or Led Strip Flexible Pcb etc.

1.Detail Flex / Rigid-flex PCB Manufacturing Capacities:

| No. | Item | Description |

| 1 | Layer | Flex board: 1-6Layers Flex-Rigid Board: 2-8Layers |

| 2 | Material | CCL, PI, PET, PEN, FR-4 |

| 3 | Final Thickness | Flex board: 0.002″ – 0.1″ (0.05-2.5mm) Flex-rigid board: 0.0024″ – 0.16″ (0.06-4.0mm) |

| 4 | Surface Treatment | Lead-free: ENG Gold; OSP, Immersion silver, Immersion Tin |

| 5 | Min Trace | Inner: 0.5oz: 4/4mil ?Outer: 1/3oz-0.5oz: 4/4mil |

| 6 | Min Width /Clearance | 1oz: 5/5mil ? ? ?1oz: 5/5mil 2oz: 5/7mil ? ? ?2oz: 5/7mil |

| 7 | Min Hole Ring | Inner: 0.5oz: 4mil ? ? Outer: 1/3oz-0.5oz: 4mil 1oz: 5/5mil ? ? ?1oz: 5/5mil 2oz: 5/7mil ? ? ?2oz: 5/7mil |

| 8 | Copper Thickness | 1/3oz – 2oz |

| 9 | Max / Min Insulation Thickness | 2mil/0.5mil (50μm/12.7μm) |

| 10 | Min Hole Size and Tolerance | Min hole: 8mil Tolerance: PTH±3mil, NPTH±2mil |

| 11 | Min Slot | 24mil x 35mil (0.6×0.9mm) |

| 12 | Solder Mask Alignment Tolerance | ±3mil |

| 13 | Silkscreen Alignment Tolerance | ±6mil |

| 14 | Silkscreen Line Width | 5mil |

| 15 | Gold Plating | Nickel: 100μ” – 200μ” ?Gold: 1μ”-4μ” |

| 16 | Immersion Nickel / Gold | Nickel: 100μ” – 200μ” ?Gold: 1μ”-5μ” |

| 17 | Nickel: 100μ” – 200μ” ?Gold: 1μ”-5μ” | Silver: 6μ” – 12μ |

| 18 | OSP | Film: 8μ” – 20μ” |

| 19 | Test Voltage | Testing Fixture: 50-300V |

| 20 | Profile Tolerance of Punch | Accurate mould: ±2mil Ordinary mould: ±4mil Knife mould: ±8mil Hand-Cut: ±15mil |

2.Delivery time:

Flexible pcb:5-9 working days,

Rigid-flex pcb:10-20 working days.

3.Package:Inner vacuum packing,Outer standard carton box packing.

4.Shipping:

A:By DHL,UPS,Fedex,TNT etc.

B:By sea for mass quantity according to customer’s requirement.

5.If need quotation for your PCB projects,pls provide following info:

A:Quote quantity,

B:Gerber file in 274-x format,

C:Technical requirement or parameters(material,layer,copper thickness,

board thickness,surface finishing,solder mask/silkscreen color…)

-

- Brand Name: Customized

- Min.Order Quantity:?No

- Supply Ability:?30~50 thousand ㎡/Month

- Port:?Shenzhen

- Service:?EMS/OEM/ODM

- Payment Terms:?T/T,Paypal,WU etc.

- Layer:?2

- Base Material:?FR4

- Copper Thickness:?1oz

- Board Thickness:?1.6mm

- Solder Mask Color:?Green(can customized)

- Silkscreen Color:?White(can customized)

- Surface Finishing:?HASL-LF

- Test Way:?100% E-Test

PRODUCT DETAIL

Green Solder Mask PCB Automotive Electrical Lighting

Also other services related to Green Solder Mask PCB,such as:Automotive PCB Board,PCB In Car,PCB for Auto Electrical Lighting etc.

1.Detail Rigid PCB Manufacturing Capabilities:

| No. | Item | Mass Production | Prototype |

| 1 | Layers | 1-8 Layers | 1-20 Layers |

| 2 | Max. Panel Size | 600*770mm( 23.62″*30.31″) | 600*770mm(23.62″*30.31″) 500*1200mm(19.69″*47.24″) |

| 3 | Max.Board Thickness | 8.5mm | 8.5mm |

| 4 | Min. Board Thickness | 2L:0.3mm, 4L:0.4mm, 6L:0.8mm |

2L:0.2mm, 4L:0.4mm. 6L:0.6mm |

| 5 | Min Inner Layer Clearance | 0.1mm(4mil) | 0.1mm(4mil) |

| 6 | Min Line width | 0.1mm(4/4 mil) | 0.075mm(3/3 mil) |

| 7 | Min Line space | 0.1mm(4/4 mil) | 0.075mm(3/3 mil) |

| 8 | Min.Hole Size | 0.15mm(8mil) | 0.1mm(6mil) |

| 9 | Min plated hole thickness | 20um(0.8mil) | 20um(0.8mil) |

| 10 | Min Blind/Buried hole size | 0.2mm(8mil) | 0.2mm(1-8layers)(8mil) |

| 11 | PTH Dia. Tolerance | ±0.076mm(±3mil) | ±0.076mm(±3mil) |

| 12 | Non PTH Dia. Tolerance | ±0.05mm(±2mil) | ±0.05mm(±2mil) |

| 13 | Hole Position Deviation | ±0.05mm(±2mil) | ±0.05mm(±2mil) |

| 14 | Heavy Coppe | 4oz/140μm | 6oz/175μm |

| 15 | Min S/M Pitch | 0.1mm (4mil) | 0.1mm (4mil) |

| 16 | Soldermask colour | Green,black,Blue,White,Yellow,Red | Green,black,Blue,White,Yellow,Red |

| 17 | Silkscreen colour | White,Yellow,Red,Black | White,Yellow,Red,Black |

| 18 | Outline | Routing,V-Groove, Beveling punch | Routing,V-Groove, Beveling punch |

| 19 | Outline Tolerance | ±0.15mm ±6mil | ±0.15mm (±6mil) |

| 20 | Peelable mask | Top,bottom,double sided | Top,bottom,double sided |

| 21 | Controlled Impedance | +/- 10% | +/- 7% |

| 22 | Insulation Resistance | 1×1012Ω(Normal) | 1×1012Ω(Normal) |

| 23 | Through Hole Resistance | <300Ω(Normal) | <300Ω(Normal) |

| 24 | Thermal Shock | 3×10sec@288℃ | 3×10sec@288℃ |

| 25 | Warp and Twist | ≤0.7% | ≤0.7% |

| 26 | Electric Strength | >1.3KV/mm | >1.4KV/mm |

| 27 | Peel Strength | 1.4N/mm | 1.4N/mm |

| 28 | Solder Mask Abrasion | >6H | >6H |

| 29 | Flammability | 94V-0 | 94V-0 |

| 30 | Test Voltage | 50-330V | 50-330V |

2.PCB lead time:(if you need urgent service,we also can meet)

| Description | Double Layer | 4 Layer | 6 Layer | 8 Layer | 10 Layer or above |

| Sample(WD) | 4 | 7 | 8 | 10 | 12 |

| Mass production(WD) | 7-9 | 10-12 | 13-15 | 16 | 20 |

3.Package:Inner vacuum packing,Outer standard carton box packing.

4.Shipping:

A:By DHL,UPS,Fedex,TNT etc.

B:By sea for mass quantity according to customer’s requirement.

5.If need quotation for your PCB projects,pls provide following info:

A:Quote quantity,

B:Gerber file in 274-x format,

C:Technical requirement or parameters(material,layer,copper thickness,

board thickness,surface finishing,solder mask/silkscreen color…)

- Brand Name: Customized

- Min.Order Quantity:?No

- Supply Ability:?30~50 thousand ㎡/Month

- Port:?Shenzhen

- Service:?EMS/OEM/ODM

- Payment Terms:?T/T,Paypal,WU etc.

- Layer:?8

- Base Material:?FR4

- Copper Thickness:?1oz

- Board Thickness:?1.6mm

- Solder Mask Color:?Blue(can customized)

- Silkscreen Color:?White(can customized)

- Surface Finishing:?Immersion Gold

- Application Industry:?Consumer Electronics

- Application Products:?Solid state drives

- Outer Line width/space:?4/4mil

- Inner Line width/space:?3.5/3.5mil

- Min.Hole Size:?0.25mm

- Test Way:?100% E-Test

- Standard:?IPC-Class2/Class 3

PRODUCT DETAIL

——————————————————————————————————————————————————————–

- Brand Name: Customized

- Min.Order Quantity:?No

- Supply Ability:?30~50 thousand ㎡/Month

- Port:?Shenzhen

- Service:?EMS/OEM/ODM

- Payment Terms:?T/T,Paypal,WU etc.

- Layer:?8

- Base Material:?FR4

- Copper Thickness:?1oz

- Board Thickness:?1.6mm

- Solder Mask Color:?Blue(can customized)

- Silkscreen Color:?White(can customized)

- Surface Finishing:?Immersion Gold

- Application Industry:?Consumer Electronics

- Application Products:?Solid state drives

- Outer Line width/space:?4/4mil

- Inner Line width/space:?3.5/3.5mil

- Min.Hole Size:?0.25mm

- Test Way:?100% E-Test

- Standard:?IPC-Class2/Class 3

PRODUCT DETAIL

——————————————————————————————————————————————————————–