- Brand Name: Customized

- Min.Order Quantity:?No

- Supply Ability:?30~50 thousand ㎡/Month

- Port:?Shenzhen

- Service:?EMS/OEM/ODM

- Payment Terms:?T/T,Paypal,WU etc.

- Layer:?6

- Base Material:?FR-4

- Copper Thickness:?1oz

- Board Thickness:?1.6mm

- Solder mask color:?Blue(can customized)

- Component labeling color:?White(can customized)

- Surface Finishing:?ENIG

- Service type:?Full assembled services

- Application:?Consumer electronics products

- Test:?E-test,AOI,X-ray,Function test

- Assembly Tech:?DIP and Wave Soldering,SMT and Reflow Soldering

PRODUCT DETAIL

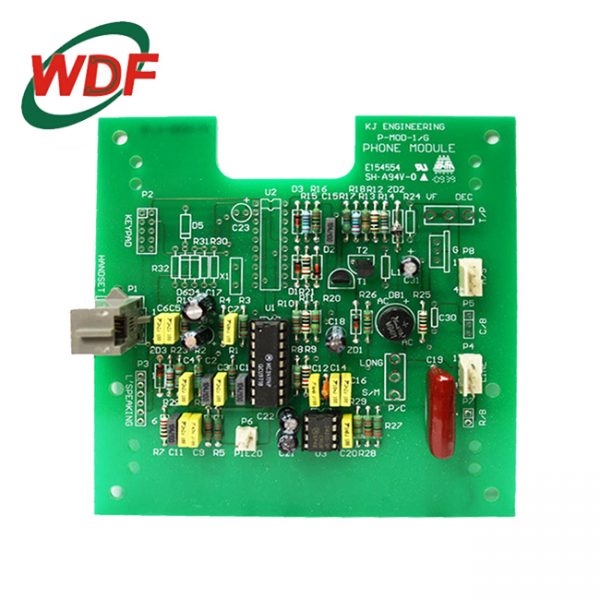

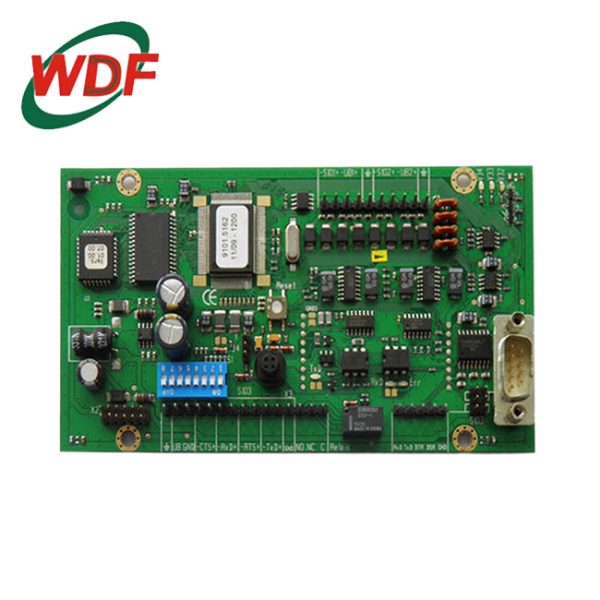

CHINA ?PCB assembly service SMT PCBA Manufacturer ?for electric appliance ??

??Advantages

–?No MOQ

– OEM services provided

–?Heavy copper PCB,?Heavy gold PCB,?Blind / Buried via PCB,?High layer count PCB? manufacturable

– Factory direct price

– Replying with price?in?one working day

– Shipping?within 24 hours

– Certificate: ROHS, UL, ISO9001-2000, ISO14001,SGS Lead-Free

Our PCBA Capability

SMT, PTH, mixed technology

SMT: 2,000,000 solder joints per day

DIP: 300,000 joints per day

Ultra fine pitch, QFP, BGA, μBGA, CBGA

Advanced SMT assembly

Automated insertion of PTH (axial, radial, dip)

Cleanable, aqueous and lead-free processing

RF manufacturing expertise

Peripheral process capabilities

Pressfit back planes & mid planes

Device programming

Automated conformal coating

For E-Test

Universal Tester

Flying Probe Open/Short Tester

High power Microscope

Solder ability Testing Kit

Peel Strength tester

High Volt Open & Short tester

Cross Section Molding Kit With Polisher

| If you need PCB assembly service as well, could you give us following information? | |

| 1. | Gerber file?of the bare PCB board |

| 2. | BOM(Bill of material) for assembly |

| To short the Lead time, please kindly advise us if there is any acceptable components substitution. | |

| 3. | Testing Guide?&?Test Fixtures, if necessary |

| 4. | Programming files?&?Programming tool, is necessary |

| 5. | Schematic, if necessary |

Our Production Capability for PCB

| Number of Layer | 1 – 20 Layer |

| Maximum Processing Area | 680 × 1000MM |

| Min Board Thickness | 2 Layer – 0.3MM ( 12 mil ) |

| 4 Layer – 0.4MM ( 16 mil ) | |

| 6 Layer – 0.8MM ( 32 mil ) | |

| 8 Layer – 1.0MM ( 40 mil) | |

| 10 Layer – 1.1MM ( 44 mil ) | |

| 12 Layer – 1.3MM ( 52 mil ) | |

| 14 Layer – 1.5MM ( 59 mil ) | |

| 16 Layer – 1.6MM ( 63 mil ) | |

| 18 Layer – 1.8MM ( 71 mil ) | |

| Finished Board Thickness Tolerance | Thickness ≤ 1.0MM, Tolerance: ± 0.1MM |

| 1.0MM ≤ Thickness ≤ 6.5MM, Tolerance ± 10% | |

| Twisting and Bending | ≤ 0.75%, Min: 0.5% |

| Range of TG | 130 – 215 ℃ |

| Impedance Tolerance | ± 10%, Min: ± 5% |

| Hi-Pot Test | Max: 4000V/10MA/60S |

| Surface Treatment | HASL, With Lead, HASL Free Lead |

| Flash Gold, Immersion Gold | |

| Immersion Silver, Immersion Tin | |

| Gold Finger, OSP |

We?provide OEM services?to all sorts of printed circuit board assembly as well as electronic encased products.

Contact us to check out full details, we will reply to you with prices?in one working day!

Contact us to check out full details, we will reply to you with prices?in one working day!

1.Which type of PCBs do you expert in?

We are specialized in producing HDI multilayer blind, BGA, impedance, half-hole, double-sided, single-sided, etc.

2.Experience?

We are OEM on PCB boards with experience over 15 years.

3.What is your Lead time?

Lead time is usually punctual here, for some special situation, we can also advise customer in advance to avoid any inexpectation or loss at customer side.

4.What is your testing policy and how you controle the quality?

For sample, usually tested by flying probe; for PCB Volume over 3 square meters, usually tested by fixture, this will be more faster. Due to there’s many steps to PCB production, we usually do inspection after every step.

5.What is your certificate?

ISO9001, ISO14001, UL, RoHS report. We can provide the report of raw material based on customer’s requirement.

6.What is your package?

With Inner vacuum package and out carton.

7.PCB shipment?

This is depend on customer, sometimes we ship through our forwarder, who is also the agency of DHL, TNT, UPS, Fedex, and so on. Our forwarder can provide too much better freight cost than we get directly from those express enterprise.

8.What is your produce ability?

Our ability is average 40,000 square meters per month.

9.I only have the pcb sample, not pcb file, can you produce it for me?

Yes, we can copy file based on your sample, this file names gerber, and production then is accorded to gerber file.

10.Can you design gerber file?

We can design gerber file if customer can provide us schematic, schematic sample can also be provided if customer want.

11.What kind of PCB file format can you accept for production? What CAM software do you use?

We accept Gerber file for production. CAM350, GENESIS, UCAM, GC-CAM, V-2000.

12.Will you allow me to put several part number together into one panel?

Yes, this is usually happen in we factory, this way can help customers reduce some cost and to a certain degree, it can help reduce some assembly cost.

13.What material brand you use for your PCB?

KB, SL, NANYA, TACONIC, ROGERS and so on.

14.What is your minimum order quantity?

We have no limitation on MOQ, prototype, medium volume and large volume are all acceptable.

15.Will RoHS Lead-Free Custom Spec. Boards be marked with lead-free symbol?

Yes, can, but need customer to specify this requirement in file.

16.Are my design files safe when I submit them to you for manufacturing?

Any customer’s file will be protected very well here in our factory and we will not let any third party know. We can sign NDA with you.

17.What is the largest PCB size you can fabricate?

- Brand Name: Customized

- Min.Order Quantity:?No

- Supply Ability:?30~50 thousand ㎡/Month

- Port:?Shenzhen

- Service:?EMS/OEM/ODM

- Payment Terms:?T/T,Paypal,WU etc.

- Layer:?6

- Base Material:?FR-4

- Copper Thickness:?1oz

- Board Thickness:?1.6mm

- Solder mask color:?Blue(can customized)

- Component labeling color:?White(can customized)

- Surface Finishing:?ENIG

- Service type:?Full assembled services

- Application:?Consumer electronics products

- Test:?E-test,AOI,X-ray,Function test

- Assembly Tech:?DIP and Wave Soldering,SMT and Reflow Soldering

PRODUCT DETAIL

Multilayer PCB Promotion In?June

–?12%?discount for multilayer PCBs

– more surprises for?regular customers

Deadline: July 5th,2015

–?No MOQ

– OEM services provided

–?Heavy copper PCB,?Heavy gold PCB,?Blind / Buried via PCB,?High layer count PCB? manufacturable

– Factory direct price

– Replying with price?in?one working day

– Shipping?within 24 hours

– Certificate: ROHS, UL, ISO9001-2000, ISO14001,SGS Lead-Free

| PCB General Capability | |

| Number of Layer | 1 – 20 Layer |

| Maximum Processing Area | 680 × 1000MM |

| Min Board Thickness | 2 Layer – 0.3MM ( 12 mil ) |

| 4 Layer – 0.4MM ( 16 mil ) | |

| 6 Layer – 0.8MM ( 32 mil ) | |

| 8 Layer – 1.0MM ( 40 mil) | |

| 10 Layer – 1.1MM ( 44 mil ) | |

| 12 Layer – 1.3MM ( 52 mil ) | |

| 14 Layer – 1.5MM ( 59 mil ) | |

| 16 Layer – 1.6MM ( 63 mil ) | |

| 18 Layer – 1.8MM ( 71 mil ) | |

| Finished Board Thickness Tolerance | Thickness ≤ 1.0MM, Tolerance: ± 0.1MM |

| 1.0MM ≤ Thickness ≤ 6.5MM, Tolerance ± 10% | |

| Twisting and Bending | ≤ 0.75%, Min: 0.5% |

| Range of TG | 130 – 215 ℃ |

| Impedance Tolerance | ± 10%, Min: ± 5% |

| Hi-Pot Test | Max: 4000V/10MA/60S |

| Surface Treatment | HASL, With Lead, HASL Free Lead |

| Flash Gold, Immersion Gold | |

| Immersion Silver, Immersion Tin | |

| Gold Finger, OSP | |

| PCB Cu Thickness + Plating | |

| Out Layer Cu Thickness | 1 – 6OZ |

| Inner Layer Cu Thickness | 0.5 – 4OZ |

| Cu Thickness of PTH | 20UM ≤ Average ≤ 25UM |

| Min: 18UM | |

| HASL with Lead | Tin 63% Lead 37% |

| HASL Free Lead | 7UM ≤ Surface Thickness ≤ 12UM |

| Thick Gold Plating | Ni Thickness: 3 – 5UM ( 120u” – 200u” ) |

| Gold Thickness: 0.025 – 1.27UM ( 1u” – 50u” ) | |

| Immersion Gold | Ni Thckness: 3 – 5UM ( 120u” – 200u” ) |

| Gold Thickness: 0.025 – 0.15UM ( 1u” – 3u” ) | |

| Immersion Silver | Ag Thickness: 0.15- 0.75 UM ( 6u” – 30u” ) |

| Gold Finger | Ni Thickness: 3 – 5UM ( 120u” – 160u” ) |

| Gold Thickness: 0.025 – 1.51UM ( 1u” – 60u” ) | |

| U940 PCB Pattern Limit Capability | |

| Min Width | 0.075MM ( 3 mil ) |

| Min Trace | 0.075MM ( 3 mil ) |

| Min Width of Ring ( Inner Layer ) | 0.15MM ( 6 mil ) |

| Min Width of Ring ( Out Layer ) | 0.1MM ( 4 mil ) |

| Min Solder Bridge | 0.1MM ( 4 mil ) |

| Min Height of Legend | 0.7MM ( 28 mil ) |

| Min Width of Legend | 0.15MM ( 6 mil ) |

| PCB Holes Processing Capability | |

| Final Hole Size | Min: Laser 0.1MM, Machine 0.2MM |

| Drilling Hole Size | 0.10 – 6.5MM |

| Drilling Tolerance | NPTH: ±0.05MM, PTH: ±0.075MM |

| Final Hole Size Tolerance ( PTH ) | φ0.20 – 1.60MM ± 0.075MM |

| φ1.60 – 6.30MM ± 0.10MM | |

| Final Hole Size Tolerance ( NPTH ) | φ0.20 – 1.60MM ± 0.05MM |

| φ1.60 – 6.50MM ± 0.05MM | |

| Drilling Strip Hole | -0L ~tu.’gth /width 2:1 |

| Min Strip Hole Width 0.65MM | |

| Length & Width Tolerance ± 0.05MM | |

| Board Thickness / Hole Size | ≤ 10:1 |

| PCB Cover Thickness Capability | |

| Solder Mask Color | Green,Matte Green,Yellow,Blue,Red,Black,Matte Black,White |

| Solder Mask Thickness | Surface Line ≥ 10UM |

| Surface Line Corner ≥ 6UM | |

| Surface Board 10 – 25UM | |

| Solder Mask Bridge Width | |

| Legend Color | White,Yellow,Black |

| Min Height of Legend | 0.70MM ( 28 mil ) |

| Min Width of Legend | 0.15MM ( 6 mil ) |

| Blue Gel Thickness | 0.2 – 1.5MM |

| Blue Gel Tolerance | ±0.15MM |

| Carbon Print Thickness | 5 – 25UM |

| Carbon Print Min Space | 0.25MM |

| Carbon Print Impedance | 200Ω |

| Blind/Burried/Half Via PCB Capability | |

| Parameters | (1+1)e.g.(4-layer)blind via:1-2,2-4(6-layer)buried via:2-3,3-4

(8-layer)blind/buried:1-3,4-5,6-8 |

| Min Via | Laser 0.1MM, Machine 0.2MM |

| Half Via | Min: 0.6MM |

| Impedance Capability | |

| Resistance Value | Single-ended 50 – 75Ω, Difference 100Ω, Coplanar 50 – 75Ω |

Our PCBA Capability

SMT, PTH, mixed technology

SMT: 2,000,000 solder joints per day

DIP: 300,000 joints per day

Ultra fine pitch, QFP, BGA, μBGA, CBGA

Advanced SMT assembly

Automated insertion of PTH (axial, radial, dip)

Cleanable, aqueous and lead-free processing

RF manufacturing expertise

Peripheral process capabilities

Pressfit back planes & mid planes

Device programming

Automated conformal coating

For E-Test

Universal Tester

Flying Probe Open/Short Tester

High power Microscope

Solder ability Testing Kit

Peel Strength tester

High Volt Open & Short tester

Cross Section Molding Kit With Polisher

| If you need PCB assembly service as well, could you give us following information? | |

| 1. | Gerber file?of the bare PCB board |

| 2. | BOM(Bill of material) for assembly |

| To short the Lead time, please kindly advise us if there is any acceptable components substitution. | |

| 3. | Testing Guide?&?Test Fixtures, if necessary |

| 4. | Programming files?&?Programming tool, is necessary |

| 5. | Schematic, if necessary |

Our Production Capability for PCB

| Number of Layer | 1 – 20 Layer |

| Maximum Processing Area | 680 × 1000MM |

| Min Board Thickness | 2 Layer – 0.3MM ( 12 mil ) |

| 4 Layer – 0.4MM ( 16 mil ) | |

| 6 Layer – 0.8MM ( 32 mil ) | |

| 8 Layer – 1.0MM ( 40 mil) | |

| 10 Layer – 1.1MM ( 44 mil ) | |

| 12 Layer – 1.3MM ( 52 mil ) | |

| 14 Layer – 1.5MM ( 59 mil ) | |

| 16 Layer – 1.6MM ( 63 mil ) | |

| 18 Layer – 1.8MM ( 71 mil ) | |

| Finished Board Thickness Tolerance | Thickness ≤ 1.0MM, Tolerance: ± 0.1MM |

| 1.0MM ≤ Thickness ≤ 6.5MM, Tolerance ± 10% | |

| Twisting and Bending | ≤ 0.75%, Min: 0.5% |

| Range of TG | 130 – 215 ℃ |

| Impedance Tolerance | ± 10%, Min: ± 5% |

| Hi-Pot Test | Max: 4000V/10MA/60S |

| Surface Treatment | HASL, With Lead, HASL Free Lead |

| Flash Gold, Immersion Gold | |

| Immersion Silver, Immersion Tin | |

| Gold Finger, OSP |

We?provide OEM services?to all sorts of printed circuit board assembly as well as electronic encased products.

Multilayer PCB Promotion In?June

–?12%?discount for multilayer PCBs

– more surprises for?regular customers

Deadline: July 5th,2015

–?No MOQ

– OEM services provided

–?Heavy copper PCB,?Heavy gold PCB,?Blind / Buried via PCB,?High layer count PCB? manufacturable

– Factory direct price

– Replying with price?in?one working day

– Shipping?within 24 hours

– Certificate: ROHS, UL, ISO9001-2000, ISO14001,SGS Lead-Free

| PCB General Capability | |

| Number of Layer | 1 – 20 Layer |

| Maximum Processing Area | 680 × 1000MM |

| Min Board Thickness | 2 Layer – 0.3MM ( 12 mil ) |

| 4 Layer – 0.4MM ( 16 mil ) | |

| 6 Layer – 0.8MM ( 32 mil ) | |

| 8 Layer – 1.0MM ( 40 mil) | |

| 10 Layer – 1.1MM ( 44 mil ) | |

| 12 Layer – 1.3MM ( 52 mil ) | |

| 14 Layer – 1.5MM ( 59 mil ) | |

| 16 Layer – 1.6MM ( 63 mil ) | |

| 18 Layer – 1.8MM ( 71 mil ) | |

| Finished Board Thickness Tolerance | Thickness ≤ 1.0MM, Tolerance: ± 0.1MM |

| 1.0MM ≤ Thickness ≤ 6.5MM, Tolerance ± 10% | |

| Twisting and Bending | ≤ 0.75%, Min: 0.5% |

| Range of TG | 130 – 215 ℃ |

| Impedance Tolerance | ± 10%, Min: ± 5% |

| Hi-Pot Test | Max: 4000V/10MA/60S |

| Surface Treatment | HASL, With Lead, HASL Free Lead |

| Flash Gold, Immersion Gold | |

| Immersion Silver, Immersion Tin | |

| Gold Finger, OSP | |

| PCB Cu Thickness + Plating | |

| Out Layer Cu Thickness | 1 – 6OZ |

| Inner Layer Cu Thickness | 0.5 – 4OZ |

| Cu Thickness of PTH | 20UM ≤ Average ≤ 25UM |

| Min: 18UM | |

| HASL with Lead | Tin 63% Lead 37% |

| HASL Free Lead | 7UM ≤ Surface Thickness ≤ 12UM |

| Thick Gold Plating | Ni Thickness: 3 – 5UM ( 120u” – 200u” ) |

| Gold Thickness: 0.025 – 1.27UM ( 1u” – 50u” ) | |

| Immersion Gold | Ni Thckness: 3 – 5UM ( 120u” – 200u” ) |

| Gold Thickness: 0.025 – 0.15UM ( 1u” – 3u” ) | |

| Immersion Silver | Ag Thickness: 0.15- 0.75 UM ( 6u” – 30u” ) |

| Gold Finger | Ni Thickness: 3 – 5UM ( 120u” – 160u” ) |

| Gold Thickness: 0.025 – 1.51UM ( 1u” – 60u” ) | |

| U940 PCB Pattern Limit Capability | |

| Min Width | 0.075MM ( 3 mil ) |

| Min Trace | 0.075MM ( 3 mil ) |

| Min Width of Ring ( Inner Layer ) | 0.15MM ( 6 mil ) |

| Min Width of Ring ( Out Layer ) | 0.1MM ( 4 mil ) |

| Min Solder Bridge | 0.1MM ( 4 mil ) |

| Min Height of Legend | 0.7MM ( 28 mil ) |

| Min Width of Legend | 0.15MM ( 6 mil ) |

| PCB Holes Processing Capability | |

| Final Hole Size | Min: Laser 0.1MM, Machine 0.2MM |

| Drilling Hole Size | 0.10 – 6.5MM |

| Drilling Tolerance | NPTH: ±0.05MM, PTH: ±0.075MM |

| Final Hole Size Tolerance ( PTH ) | φ0.20 – 1.60MM ± 0.075MM |

| φ1.60 – 6.30MM ± 0.10MM | |

| Final Hole Size Tolerance ( NPTH ) | φ0.20 – 1.60MM ± 0.05MM |

| φ1.60 – 6.50MM ± 0.05MM | |

| Drilling Strip Hole | -0L ~tu.’gth /width 2:1 |

| Min Strip Hole Width 0.65MM | |

| Length & Width Tolerance ± 0.05MM | |

| Board Thickness / Hole Size | ≤ 10:1 |

| PCB Cover Thickness Capability | |

| Solder Mask Color | Green,Matte Green,Yellow,Blue,Red,Black,Matte Black,White |

| Solder Mask Thickness | Surface Line ≥ 10UM |

| Surface Line Corner ≥ 6UM | |

| Surface Board 10 – 25UM | |

| Solder Mask Bridge Width | |

| Legend Color | White,Yellow,Black |

| Min Height of Legend | 0.70MM ( 28 mil ) |

| Min Width of Legend | 0.15MM ( 6 mil ) |

| Blue Gel Thickness | 0.2 – 1.5MM |

| Blue Gel Tolerance | ±0.15MM |

| Carbon Print Thickness | 5 – 25UM |

| Carbon Print Min Space | 0.25MM |

| Carbon Print Impedance | 200Ω |

| Blind/Burried/Half Via PCB Capability | |

| Parameters | (1+1)e.g.(4-layer)blind via:1-2,2-4(6-layer)buried via:2-3,3-4

(8-layer)blind/buried:1-3,4-5,6-8 |

| Min Via | Laser 0.1MM, Machine 0.2MM |

| Half Via | Min: 0.6MM |

| Impedance Capability | |

| Resistance Value | Single-ended 50 – 75Ω, Difference 100Ω, Coplanar 50 – 75Ω |

Our PCBA Capability

SMT, PTH, mixed technology

SMT: 2,000,000 solder joints per day

DIP: 300,000 joints per day

Ultra fine pitch, QFP, BGA, μBGA, CBGA

Advanced SMT assembly

Automated insertion of PTH (axial, radial, dip)

Cleanable, aqueous and lead-free processing

RF manufacturing expertise

Peripheral process capabilities

Pressfit back planes & mid planes

Device programming

Automated conformal coating

For E-Test

Universal Tester

Flying Probe Open/Short Tester

High power Microscope

Solder ability Testing Kit

Peel Strength tester

High Volt Open & Short tester

Cross Section Molding Kit With Polisher

| If you need PCB assembly service as well, could you give us following information? | |

| 1. | Gerber file?of the bare PCB board |

| 2. | BOM(Bill of material) for assembly |

| To short the Lead time, please kindly advise us if there is any acceptable components substitution. | |

| 3. | Testing Guide?&?Test Fixtures, if necessary |

| 4. | Programming files?&?Programming tool, is necessary |

| 5. | Schematic, if necessary |

Our Production Capability for PCB

| Number of Layer | 1 – 20 Layer |

| Maximum Processing Area | 680 × 1000MM |

| Min Board Thickness | 2 Layer – 0.3MM ( 12 mil ) |

| 4 Layer – 0.4MM ( 16 mil ) | |

| 6 Layer – 0.8MM ( 32 mil ) | |

| 8 Layer – 1.0MM ( 40 mil) | |

| 10 Layer – 1.1MM ( 44 mil ) | |

| 12 Layer – 1.3MM ( 52 mil ) | |

| 14 Layer – 1.5MM ( 59 mil ) | |

| 16 Layer – 1.6MM ( 63 mil ) | |

| 18 Layer – 1.8MM ( 71 mil ) | |

| Finished Board Thickness Tolerance | Thickness ≤ 1.0MM, Tolerance: ± 0.1MM |

| 1.0MM ≤ Thickness ≤ 6.5MM, Tolerance ± 10% | |

| Twisting and Bending | ≤ 0.75%, Min: 0.5% |

| Range of TG | 130 – 215 ℃ |

| Impedance Tolerance | ± 10%, Min: ± 5% |

| Hi-Pot Test | Max: 4000V/10MA/60S |

| Surface Treatment | HASL, With Lead, HASL Free Lead |

| Flash Gold, Immersion Gold | |

| Immersion Silver, Immersion Tin | |

| Gold Finger, OSP |

We?provide OEM services?to all sorts of printed circuit board assembly as well as electronic encased products.

- Brand Name: Customized

- Min.Order Quantity:?No

- Supply Ability:?30~50 thousand ㎡/Month

- Port:?Shenzhen

- Service:?EMS/OEM/ODM

- Payment Terms:?T/T,Paypal,WU etc.

- Layer:?6

- Base Material:?FR-4

- Copper Thickness:?1oz

- Board Thickness:?1.6mm

- Solder mask color:?Blue(can customized)

- Component labeling color:?White(can customized)

- Surface Finishing:?ENIG

- Service type:?Full assembled services

- Application:?Consumer electronics products

- Test:?E-test,AOI,X-ray,Function test

- Assembly Tech:?DIP and Wave Soldering,SMT and Reflow Soldering

PRODUCT DETAIL

Our Production Capability for PCB:

| Layer | 1-28 |

| Board finished thickness | 0.21mm-7.0mm |

| Material | FR-4, CEM-1,CEM-3, High TG, FR4 Halogen Free,Rogers |

| Max. finished board size | 23 × 25? ( 580mm×900mm ) |

| Min. drilled hole size | 3mil (0.075mm) |

| Min. Line width | 3mil (0.075mm) |

| Min.Line spacing | 3mil (0.075mm) |

| Surface finish/treatment | HASL / HASL lead free,HAL, Chemical tin,Chemical Gold, Immersion Silver/Gold,OSP,Gold plating |

| Copper thickness | 0.5-7.0 OZ |

| Solder mask color | green/yellow/black/white/red/blue |

| Copper thickness in hole | >25.0 um? (>1mil) |

| Inner packing | Vacuum packing / Plastic bag |

| Outer packing | Standard carton packing |

| Shape tolerance | ±0.13 |

| Hole tolerance | PTH: ±0.076?? NPTH: ±0.05 |

| Special requirements | Buried and blind vias+controlled impedance +BGA |

| Profiling | Punching, Routing, V-CUT, Beveling |

| Certificate | ROHS, UL, ISO9001-2000, ISO14001 |

|

E-Testing

|

100% E-Testing (High Voltage Testing);? Flying Probe Testing

|

|

Date file format

|

GERBER FILE and DRILLING FILE, PROTEL SERIES, PADS2000 SERIES, Powerpcb SERIES, ODB++ |

Contact us to check out great PCBs and full details, we will reply to you with prices in one working day!

- OEM services provided

- Certificate: ROHS, UL, ISO9001-2000, ISO14001

- Factory direct price

????????????

- Brand Name: Customized

- Min.Order Quantity:?No

- Supply Ability:?30~50 thousand ㎡/Month

- Port:?Shenzhen

- Service:?EMS/OEM/ODM

- Payment Terms:?T/T,Paypal,WU etc.

- Layer:?8

- Base Material:?FR4

- Copper Thickness:?1oz

- Board Thickness:?1.6mm

- Solder Mask Color:?Blue(can customized)

- Silkscreen Color:?White(can customized)

- Surface Finishing:?Immersion Gold

- Application Industry:?Consumer Electronics

- Application Products:?Solid state drives

- Outer Line width/space:?4/4mil

- Inner Line width/space:?3.5/3.5mil

- Min.Hole Size:?0.25mm

- Test Way:?100% E-Test

- Standard:?IPC-Class2/Class 3

PRODUCT DETAIL

PCB Assembly Sample Introduction

Product Details:

| Place of Origin: | China |

| Brand Name: | OEM |

| Certification: | CE,ROHS, FCC,ISO9008,SGS,UL |

| Model Number: | OEM |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

| Price: | negotiation |

| Packaging Details: | inner: vacuum-packed bubble bag outer: carton box |

| Delivery Time: | 5-10 days |

| Payment Terms: | T/T,Western union |

| Supply Ability: | 1, 000, 000 PCS / week |

Detailed Product Description

| Material: | FR4 | Layer: | 2 |

| Color: | Green | Min Line Space: | 5mil |

| Min Line Width: | 5mil | Copper Thickness: | 1OZ |

| Board Size: | 115*65mm | Panel: | 1 |

| Surface: | ENIG |

Electronic Printed Circuit Board PCB Assembly FR4 Material 1OZ Copper Thickness

Quick detail:

| Origin:China | Special: PCB Assembly |

| Layer:2 | Thickness:1.6mm |

| Surface: ENIG | Hole:0.8 |

Specification:

We also have ability for PCB layout ,PCBA and Circuit assembly, specializes in producing the various electronic products based on your customized designs and do pcba,pcb assembly for all kinds of small ,medium Volume electronic products

Enabling you to focus on product development and sales, we can solve your production technology issues and take care of product quality

The operation we can handle for you is from the Bare pc board fabrication, full component procurement, SMT/BGA/DIP assembly, mechanical/case assembly, rubber molding, functional testing, repair, inspection of finished goods to shipment arrangement

Typical Applications

SMD package, Chip-on-board and Flip Chip assembly technique

0201 chip, Micro BGA, u-BGA, QFN and LGA assembly

AI and Thru-hole assembly

RoHS, REACH compliance and Lead-Free solder technology

Chip Programming

Conformal Coating

ICT test and AOI inspection

ESD Protection Control Procedure

IPC-A-610E Class II and Class III Workmanship Standard

1) Professional Surface-mounting and Through-hole soldering Technology

2) Various sizes like 1206,0805,0603 components SMT technology

3) ICT(In Circuit Test),FCT(Functional Circuit Test) technology.

4) PCB Assembly With UL,CE,FCC,Rohs Approval

5) Nitrogen gas reflow soldering technology for SMT.

6) High Standard SMT&Solder Assembly Line

7) High density interconnected board placement technology capacity.

Parameter:

| o | Item | Data |

| 1 | Layer: | 1 to 24 layers |

| 2 | Material type: | FR-4, CEM-1, CEM-3, High TG, FR4 Halogen Free, Rogers |

| 3 | Board thickness: | 0.20mm to 3.4mm |

| 4 | Copper thickness: | 0.5 OZ to 4 OZ |

| 5 | Copper thickness in hole: | >25.0 um (>1mil) |

| 6 | Max. Board Size: | (580mm×1200mm) |

| 7 | Min. Drilled Hole Size: | 4mil(0.1mm) |

| 8 | Min. Line Width: | 3mil (0.075mm) |

| 9 | Min. Line Spacing: | 3mil (0.075mm) |

| 10 | Surface finishing: | HASL / HASL lead free, HAL, Chemical tin, Chemical Gold, Immersion Silver/Gold, OSP, Gold plating |

| 11 | Solder Mask Color: | Green/Yellow/Black/White/Red/Blue |

| 12 | Shape tolerance: | ±0.13 |

| 13 | Hole tolerance: | PTH: ±0.076 NPTH: ±0.05 |

| 14 | Package: | Inner packing: Vacuum packing / Plastic bag,Outer packing: Standard carton packing |

| 15 | Certificate: | UL,SGS,ISO 9001:2008 |

| 16 | Special requirements: | Buried and blind vias+controlled impedance +BGA |

| 17 | Profiling: | Punching, Routing, V-CUT, Beveling |

Welcome to get the customized pcb assembly fr4 material 1oz copper thickness with our professional manufacturers and suppliers. Through strict manufacturing process, we can assure you of the high quality and high efficiency of our pcb assembly fr4 material 1oz copper thickness. Please be free to contact our factory.

- Brand Name: Customized

- Min.Order Quantity:?No

- Supply Ability:?30~50 thousand ㎡/Month

- Port:?Shenzhen

- Service:?EMS/OEM/ODM

- Payment Terms:?T/T,Paypal,WU etc.

- Layer:?8

- Base Material:?FR4

- Copper Thickness:?1oz

- Board Thickness:?1.6mm

- Solder Mask Color:?Blue(can customized)

- Silkscreen Color:?White(can customized)

- Surface Finishing:?Immersion Gold

- Application Industry:?Consumer Electronics

- Application Products:?Solid state drives

- Outer Line width/space:?4/4mil

- Inner Line width/space:?3.5/3.5mil

- Min.Hole Size:?0.25mm

- Test Way:?100% E-Test

- Standard:?IPC-Class2/Class 3

PRODUCT DETAIL

PCB Assembly ?Sample Introduction

Product Details:

| Place of Origin: | China |

| Brand Name: | OEM |

| Certification: | CE,ROHS, FCC,ISO9008,SGS,UL |

| Model Number: | OEM |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

| Price: | negotiation |

| Packaging Details: | inner: vacuum-packed bubble bag outer: carton box |

| Delivery Time: | 5-10 days |

| Payment Terms: | T/T,Western union |

| Supply Ability: | 1, 000, 000 PCS / week |

Detailed Product Description

| Material: | FR4 | Layer: | 2 |

| Color: | Green | Min Line Space: | 5mil |

| Min Line Width: | 5mil | Copper Thickness: | 1OZ |

| Board Size: | 200*50mm | Panel: | 1 |

| Surface: | HASL-LF |

FR4 High TG pcb board assembly OEM Electronic Prototype Pcb Fabrication

FR4 Material High TG Assembly Board OEM Pcb Assembly Board ?Electronic Prototype Pcb Fabrication

Quick detail:

| Origin:China | Special: PCB Assembly |

| Layer:2 | Thickness:1.6mm |

| Surface: HASL-LF | Hole:0.8 |

Specification:

We also have ability for PCB layout ,PCBA and Circuit assembly, specializes in producing the various electronic products based on your customized designs and do pcba,pcb assembly for all kinds of small ,medium Volume electronic products

Enabling you to focus on product development and sales, we can solve your production technology issues and take care of product quality

The operation we can handle for you is from the Bare pc board fabrication, full component procurement, SMT/BGA/DIP assembly, mechanical/case assembly, rubber molding, functional testing, repair, inspection of finished goods to shipment arrangement

Typical Applications

SMD package, Chip-on-board and Flip Chip assembly technique

0201 chip, Micro BGA, u-BGA, QFN and LGA assembly

AI and Thru-hole assembly

RoHS, REACH compliance and Lead-Free solder technology

Chip Programming

Conformal Coating

ICT test and AOI inspection

ESD Protection Control Procedure

IPC-A-610E Class II and Class III Workmanship Standard

1) Professional Surface-mounting and Through-hole soldering Technology

2) Various sizes like 1206,0805,0603 components SMT technology

3) ICT(In Circuit Test),FCT(Functional Circuit Test) technology.

4) PCB Assembly With UL,CE,FCC,Rohs Approval

5) Nitrogen gas reflow soldering technology for SMT.

6) High Standard SMT&Solder Assembly Line

7) High density interconnected board placement technology capacity.

Parameter:

| o | Item | Data |

| 1 | Layer: | 1 to 24 layers |

| 2 | Material type: | FR-4, CEM-1, CEM-3, High TG, FR4 Halogen Free, Rogers |

| 3 | Board thickness: | 0.20mm to 3.4mm |

| 4 | Copper thickness: | 0.5 OZ to 4 OZ |

| 5 | Copper thickness in hole: | >25.0 um (>1mil) |

| 6 | Max. Board Size: | (580mm×1200mm) |

| 7 | Min. Drilled Hole Size: | 4mil(0.1mm) |

| 8 | Min. Line Width: | 3mil (0.075mm) |

| 9 | Min. Line Spacing: | 3mil (0.075mm) |

| 10 | Surface finishing: | HASL / HASL lead free, HAL, Chemical tin, Chemical Gold, Immersion Silver/Gold, OSP, Gold plating |

| 11 | Solder Mask Color: | Green/Yellow/Black/White/Red/Blue |

| 12 | Shape tolerance: | ±0.13 |

| 13 | Hole tolerance: | PTH: ±0.076 NPTH: ±0.05 |

| 14 | Package: | Inner packing: Vacuum packing / Plastic bag,Outer packing: Standard carton packing |

| 15 | Certificate: | UL,SGS,ISO 9001:2008 |

| 16 | Special requirements: | Buried and blind vias+controlled impedance +BGA |

| 17 | Profiling: | Punching, Routing, V-CUT, Beveling |

Welcome to get the customized pcb assembly sample introduction with our professional manufacturers and suppliers. Through strict manufacturing process, we can assure you of the high quality and high efficiency of our pcb assembly sample introduction. Please be free to contact our factory.

- Brand Name: Customized

- Min.Order Quantity:?No

- Supply Ability:?30~50 thousand ㎡/Month

- Port:?Shenzhen

- Service:?EMS/OEM/ODM

- Payment Terms:?T/T,Paypal,WU etc.

- Layer:?6

- Base Material:?FR-4

- Copper Thickness:?1oz

- Board Thickness:?1.6mm

- Solder mask color:?Blue(can customized)

- Component labeling color:?White(can customized)

- Surface Finishing:?ENIG

- Service type:?Full assembled services

- Application:?Consumer electronics products

- Test:?E-test,AOI,X-ray,Function test

- Assembly Tech:?DIP and Wave Soldering,SMT and Reflow Soldering

PRODUCT DETAIL

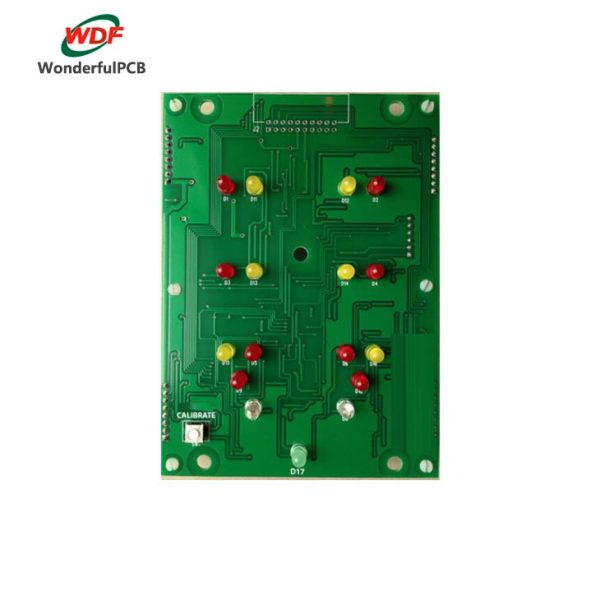

Specification:

We also have ability for PCB layout ,PCBA and Circuit assembly, specializes in producing the various electronic products based on your customized designs and do pcba,pcb assembly for all kinds of small ,medium Volume electronic products

Enabling you to focus on product development and sales, we can solve your production technology issues and take care of product quality

The operation we can handle for you is from the Bare pc board fabrication, full component procurement, SMT/BGA/DIP assembly, mechanical/case assembly, rubber molding, functional testing, repair, inspection of finished goods to shipment arrangement

Typical Applications

SMD package, Chip-on-board and Flip Chip assembly technique

0201 chip, Micro BGA, u-BGA, QFN and LGA assembly

AI and Thru-hole assembly

RoHS, REACH compliance and Lead-Free solder technology

Chip Programming

Conformal Coating

ICT test and AOI inspection

ESD Protection Control Procedure

IPC-A-610E Class II and Class III Workmanship Standard

1) Professional Surface-mounting and Through-hole soldering Technology

2) Various sizes like 1206,0805,0603 components SMT technology

3) ICT(In Circuit Test),FCT(Functional Circuit Test) technology.

4) PCB Assembly With UL,CE,FCC,Rohs Approval

5) Nitrogen gas reflow soldering technology for SMT.

6) High Standard SMT&Solder Assembly Line

7) High density interconnected board placement technology capacity.