- Brand Name: Customized

- Min.Order Quantity:?No

- Supply Ability:?30~50 thousand ㎡/Month

- Port:?Shenzhen

- Service:?EMS/OEM/ODM

- Payment Terms:?T/T,Paypal,WU etc.

- Layer:?2

- Base Material:?Polyimide

- Copper Thickness:?1oz

- Board Thickness:?0.15mm

- Solder Mask Color:?White

- Silkscreen Color:?Yellow cover film

- Surface Finishing:?Immersion Gold

- Test Way:?100% E-Test

- Standard:?IPC-Class2/Class 3

PRODUCT DETAIL

Rigid-flex circuits are a hybrid construction flex circuit consisting of rigid and flexible substrates which are laminated together into a single structure.

The layers of a rigid flex are also normally electrically interconnected by means of plated through holes. Rigid-flex boards are normally multilayer structures.

We have industry-leading equipment and engineering teams to complete your time-sensitive requirements of PCB fabrication. Short-turn needs or constant high-volume supplying, we would provide service to meet your standards. Printed circuit board is a self-contained module of interconnected electronic components found in devices ranging from common beepers, or pagers, and radios to sophisticated radar and computer systems. It has a great deal of advantages, compared to older ways of building electronics.

It may have circuits that perform a single function, such as a signal amplifier, or multiple functions. We offer outstanding product services with qualities and we have been well-known in the PCB markets throughout worldwide. We have the best and the most modern facilities manufacturing all our products as, way better than other providers. Therefore, we will be the very only printed circuit board manufacturing partner to satisfy your needs.

Our PCB fabrication is available in various materials such as aluminum, copper, metal core, polyester etc. Also, we offer custom service to meet your particular requirement. For further information and details about our product, please take a look of our showroom, or send your inquiry to us.

Our Production Capability for PCB

| Number of Layer | 1 – 20 Layer |

| Maximum Processing Area | 680 × 1000MM |

| Min Board Thickness | 2 Layer – 0.3MM ( 12 mil ) |

| 4 Layer – 0.4MM ( 16 mil ) | |

| 6 Layer – 0.8MM ( 32 mil ) | |

| 8 Layer – 1.0MM ( 40 mil) | |

| 10 Layer – 1.1MM ( 44 mil ) | |

| 12 Layer – 1.3MM ( 52 mil ) | |

| 14 Layer – 1.5MM ( 59 mil ) | |

| 16 Layer – 1.6MM ( 63 mil ) | |

| 18 Layer – 1.8MM ( 71 mil ) | |

| Finished Board Thickness Tolerance | Thickness ≤ 1.0MM, Tolerance: ± 0.1MM |

| 1.0MM ≤ Thickness ≤ 6.5MM, Tolerance ± 10% | |

| Twisting and Bending | ≤ 0.75%, Min: 0.5% |

| Range of TG | 130 – 215 ℃ |

| Impedance Tolerance | ± 10%, Min: ± 5% |

| Hi-Pot Test | Max: 4000V/10MA/60S |

| Surface Treatment | HASL, With Lead, HASL Free Lead |

| Flash Gold, Immersion Gold | |

| Immersion Silver, Immersion Tin | |

| Gold Finger, OSP |

- Brand Name: Customized

- Min.Order Quantity:?No

- Supply Ability:?30~50 thousand ㎡/Month

- Port:?Shenzhen

- Service:?EMS/OEM/ODM

- Payment Terms:?T/T,Paypal,WU etc.

- Layer:?2

- Base Material:?Polyimide

- Copper Thickness:?1oz

- Board Thickness:?0.15mm

- Solder Mask Color:?White

- Silkscreen Color:?Yellow cover film

- Surface Finishing:?Immersion Gold

- Test Way:?100% E-Test

- Standard:?IPC-Class2/Class 3

PRODUCT DETAIL

Rigid-flex circuits are a hybrid construction flex circuit consisting of rigid and flexible substrates which are laminated together into a single structure.

The layers of a rigid flex are also normally electrically interconnected by means of plated through holes. Rigid-flex boards are normally multilayer structures.

We have industry-leading equipment and engineering teams to complete your time-sensitive requirements of PCB fabrication. Short-turn needs or constant high-volume supplying, we would provide service to meet your standards. Printed circuit board is a self-contained module of interconnected electronic components found in devices ranging from common beepers, or pagers, and radios to sophisticated radar and computer systems. It has a great deal of advantages, compared to older ways of building electronics.

It may have circuits that perform a single function, such as a signal amplifier, or multiple functions. We offer outstanding product services with qualities and we have been well-known in the PCB markets throughout worldwide. We have the best and the most modern facilities manufacturing all our products as, way better than other providers. Therefore, we will be the very only printed circuit board manufacturing partner to satisfy your needs.

Our PCB fabrication is available in various materials such as aluminum, copper, metal core, polyester etc. Also, we offer custom service to meet your particular requirement. For further information and details about our product, please take a look of our showroom, or send your inquiry to us.

flex board design ?with assembling

1.FPC soldering

2.1~8layer FPC manufacture

3.FPC fast prototype

4.FPC assembly service

5.Min.Order is 1 piece

Our Production Capability for FPC:

| Layers | ?????? 1-8layers |

| Finished Board Thickness | 0.1-0.2mm |

| Max.(Min.)panel size | 600*250mm |

| Available Laminates Material | PI, PET,ED, RA |

| Finished Board Thickness tolerance | ±10% |

| Finished hole diameter(Min) | 0.2mm |

| Finished Hole diameter(Max) | 6mm |

| NPTH Hole diameter tolerance | ±0.05mm |

| PTH Hole Diameter tolerance | ±0.05mm |

| Copper foil thickness | 9/12/18/35/70um |

| Circuit width/spacing(Min) | 0.075mm |

| Surface Finished type | immersion tin |

| immersion gold | |

| OSP | |

| plated gold | |

| plate tin | |

| Gold flash Ni/Au thickness | 1-3U |

| Immersion Tin thickness | 6-12um |

| Tin platig thickeess | 10-15um |

| Drill hole position tolerance | ±0.075mm |

| Punching dimension tolerance | ±0.05mm |

- Brand Name: Customized

- Min.Order Quantity:?No

- Supply Ability:?30~50 thousand ㎡/Month

- Port:?Shenzhen

- Service:?EMS/OEM/ODM

- Payment Terms:?T/T,Paypal,WU etc.

- Layer:?2

- Base Material:?Polyimide

- Copper Thickness:?1oz

- Board Thickness:?0.15mm

- Solder Mask Color:?White

- Silkscreen Color:?Yellow cover film

- Surface Finishing:?Immersion Gold

- Test Way:?100% E-Test

- Standard:?IPC-Class2/Class 3

PRODUCT DETAIL

Rigid-flex circuits are a hybrid construction flex circuit consisting of rigid and flexible substrates which are laminated together into a single structure.

The layers of a rigid flex are also normally electrically interconnected by means of plated through holes. Rigid-flex boards are normally multilayer structures.

We have industry-leading equipment and engineering teams to complete your time-sensitive requirements of PCB fabrication. Short-turn needs or constant high-volume supplying, we would provide service to meet your standards. Printed circuit board is a self-contained module of interconnected electronic components found in devices ranging from common beepers, or pagers, and radios to sophisticated radar and computer systems. It has a great deal of advantages, compared to older ways of building electronics.

It may have circuits that perform a single function, such as a signal amplifier, or multiple functions. We offer outstanding product services with qualities and we have been well-known in the PCB markets throughout worldwide. We have the best and the most modern facilities manufacturing all our products as, way better than other providers. Therefore, we will be the very only printed circuit board manufacturing partner to satisfy your needs.

Our PCB fabrication is available in various materials such as aluminum, copper, metal core, polyester etc. Also, we offer custom service to meet your particular requirement. For further information and details about our product, please take a look of our showroom, or send your inquiry to us.

Our Production Capability for PCB:

| Layer | 1-28 |

| Board finished thickness | 0.21mm-7.0mm |

| Material | FR-4, CEM-1,CEM-3, High TG, FR4 Halogen Free,Rogers |

| Max. finished board size | 23 × 25? ( 580mm×900mm ) |

| Min. drilled hole size | 3mil (0.075mm) |

| Min. Line width | 3mil (0.075mm) |

| Min.Line spacing | 3mil (0.075mm) |

| Surface finish/treatment | HASL / HASL lead free,HAL, Chemical tin,Chemical Gold, Immersion Silver/Gold,OSP,Gold plating |

| Copper thickness | 0.5-7.0 OZ |

| Solder mask color | green/yellow/black/white/red/blue |

| Copper thickness in hole | >25.0 um? (>1mil) |

| Inner packing | Vacuum packing / Plastic bag |

| Outer packing | Standard carton packing |

| Shape tolerance | ±0.13 |

| Hole tolerance | PTH: ±0.076?? NPTH: ±0.05 |

| Special requirements | Buried and blind vias+controlled impedance +BGA |

| Profiling | Punching, Routing, V-CUT, Beveling |

| Certificate | ROHS, UL, ISO9001-2000, ISO14001 |

|

E-Testing

|

100% E-Testing (High Voltage Testing);? Flying Probe Testing

|

|

Date file format

|

GERBER FILE and DRILLING FILE, PROTEL SERIES, PADS2000 SERIES, Powerpcb SERIES, ODB++ |

Contact us to check out great PCBs and full details, we will reply to you with prices in one working day!

- OEM services provided

- Certificate: ROHS, UL, ISO9001-2000, ISO14001

- Factory direct price

- Brand Name: Customized

- Min.Order Quantity:?No

- Supply Ability:?30~50 thousand ㎡/Month

- Port:?Shenzhen

- Service:?EMS/OEM/ODM

- Payment Terms:?T/T,Paypal,WU etc.

- Layer:?2

- Base Material:?Polyimide

- Copper Thickness:?1oz

- Board Thickness:?0.15mm

- Solder Mask Color:?White

- Silkscreen Color:?Yellow cover film

- Surface Finishing:?Immersion Gold

- Test Way:?100% E-Test

- Standard:?IPC-Class2/Class 3

PRODUCT DETAIL

Rigid-flex circuits are a hybrid construction flex circuit consisting of rigid and flexible substrates which are laminated together into a single structure.

The layers of a rigid flex are also normally electrically interconnected by means of plated through holes. Rigid-flex boards are normally multilayer structures.

We have industry-leading equipment and engineering teams to complete your time-sensitive requirements of PCB fabrication. Short-turn needs or constant high-volume supplying, we would provide service to meet your standards. Printed circuit board is a self-contained module of interconnected electronic components found in devices ranging from common beepers, or pagers, and radios to sophisticated radar and computer systems. It has a great deal of advantages, compared to older ways of building electronics.

It may have circuits that perform a single function, such as a signal amplifier, or multiple functions. We offer outstanding product services with qualities and we have been well-known in the PCB markets throughout worldwide. We have the best and the most modern facilities manufacturing all our products as, way better than other providers. Therefore, we will be the very only printed circuit board manufacturing partner to satisfy your needs.

Our PCB fabrication is available in various materials such as aluminum, copper, metal core, polyester etc. Also, we offer custom service to meet your particular requirement. For further information and details about our product, please take a look of our showroom, or send your inquiry to us.

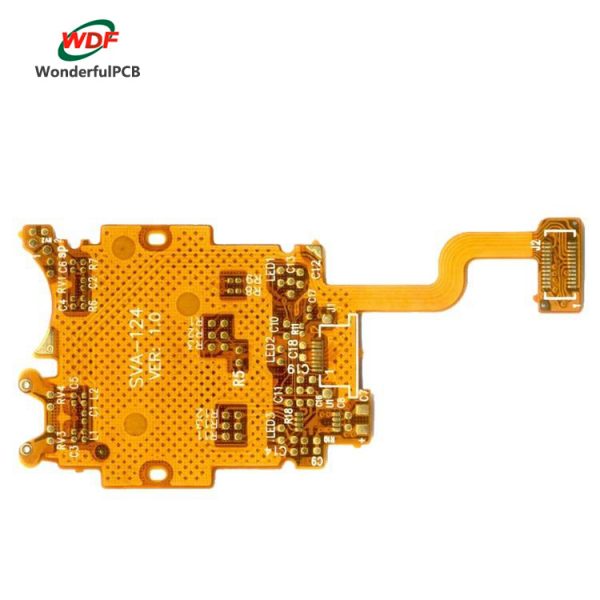

Specifications

fpc supplier in Shenzhen China:

1) Material: PI

2) Finish: ENIG

3) Solder Mask: Yellow

Our Production Capability for PCB:

| Layer | 1-28 |

| Board finished thickness | 0.21mm-7.0mm |

| Material | FR-4, CEM-1,CEM-3, High TG, FR4 Halogen Free,Rogers |

| Max. finished board size | 23 × 25? ( 580mm×900mm ) |

| Min. drilled hole size | 3mil (0.075mm) |

| Min. Line width | 3mil (0.075mm) |

| Min.Line spacing | 3mil (0.075mm) |

| Surface finish/treatment | HASL / HASL lead free,HAL, Chemical tin,Chemical Gold, Immersion Silver/Gold,OSP,Gold plating |

| Copper thickness | 0.5-7.0 OZ |

| Solder mask color | green/yellow/black/white/red/blue |

| Copper thickness in hole | >25.0 um? (>1mil) |

| Inner packing | Vacuum packing / Plastic bag |

| Outer packing | Standard carton packing |

| Shape tolerance | ±0.13 |

| Hole tolerance | PTH: ±0.076?? NPTH: ±0.05 |

| Special requirements | Buried and blind vias+controlled impedance +BGA |

| Profiling | Punching, Routing, V-CUT, Beveling |

| Certificate | ROHS, UL, ISO9001-2000, ISO14001 |

|

E-Testing

|

100% E-Testing (High Voltage Testing);? Flying Probe Testing

|

|

Date file format

|

GERBER FILE and DRILLING FILE, PROTEL SERIES, PADS2000 SERIES, Powerpcb SERIES, ODB++ |

PRODUCT DETAIL

Flexible PCB

Flexible printed circuit boards derive their name for their ability to enable the circuitry to be designed to fit the electronic device or product, as opposed to building the device to conform with the circuit board. Flex boards are characterized by a distinctly patterned printed circuitry and component arrangement highlighted by a malleable base material.

Exploring the Many Advantages of Flex Circuit Boards

Flexible printed circuit boards offer a number of potential benefits including:

??Saving Space:?Flex PCB design requires only about 10 percent of the space and weight of a wired circuit board assembly, offering greater installation and packaging freedom. The inherent flexibility also permits tighter bend capabilities.

??Maximum Reliability:?A flexible printed circuit board requires fewer interconnects, which in turn require fewer contact crimps, connectors and solder joints. Simply put, a flexible PCB board does not contain as many potential sources for failure, which enhances their reliability.

??Enhanced Capabilities:?The flexible PCB is compatible with virtually any type of connector or component and works well with options such as ZIP connectors. They also perform extremely well in extreme temperatures and offer superior resistance to radiation and chemicals.

??Cost Savings:?Cost-saving advantages of flexible printed circuits include reduced material and packaging requirements, lower parts replacement costs and a reduction in assembly errors that could otherwise result in the need for repairs.

All of these benefits make flex circuit boards ideally suited for a wide range of applications in industries such as Military, Transportation, Medical, Consumer Electronics, Automotive, Aerospace, Communications and Industrial.

Wells: A Leading Flex PCB Manufacturer for More Than a Decade

At Wells, we specialize in the fabrication and assembly of flexible printed circuit products for use in the manufacturing of medical devices and various types of telecommunication and industrial equipment. Our custom PCB manufacturing capabilities allow us to develop and produce a top-performing flex PCB that meets your unique requirements. We can also work with you to produce a custom flex PCB prototype that will significantly improve your prospects of a successful project outcome.

| Item | Capability |

| Quality Grade | Standard IPC 2 |

| Number of Layers | 1-8layers |

| Order Quantity | 1pc-10000+pcs |

| Build Time | 2days-5weeks |

| Material | DuPont PI, Domestic Shengyi PI |

| Board Size | Min 6*6mm, Max 406*610mm |

| Board Thickness | 0.6mm-2.0mm |

| Copper Weight (Finished) | 0.5oz-2.0oz |

| Min Tracing/Spacing | 3mil/3mil |

| Solder Mask Sides | As per the file |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Solder-stop coating—Soldermask oil | Green, White, Blue, Black, Red, Yellow |

| Solder-stop coating—Coverlay | PI and PET film |

| Silkscreen Sides | As per the file |

| Silkscreen Color | White, Black, Yellow |

| Surface Finish | HASL-Hot air solder leveling Lead-free HASL-RoHS ENIG-RoHS Immersion Tin-RoHS OSP-RoHS |

| Min Annular Ring | 4mil |

| Min Drilling Hole Diameter | 8mil |

| Min. hole size—Drilling (PTH) | 0.2mil |

| Min. hole size—Punching (NPTH) | 0.5mil |

| Tolerance of dimension | ±0.05mm |

| Other Techniques | Peelable solder mask Gold fingers Stiffener (only for PI/FR4 substrate) |

Our High-Quality Flexible PCB Manufacturing Process

A key reason why Wells is widely regarded as a top PCB manufacturer is our unwavering commitment to quality. Our experienced team checks each design and takes the time to review it with you prior to production. This ensures the circuit design is ready for manufacturing, and your boards will deliver the performance you expect. We guarantee the quality of our flex PCB parts and components.

Welcome to get the customized flex pcb with our professional manufacturers and suppliers. Through strict manufacturing process, we can assure you of the high quality and high efficiency of our flex pcb. Please be free to contact our factory.

- Brand Name: Customized

- Min.Order Quantity:?No

- Supply Ability:?30~50 thousand ㎡/Month

- Port:?Shenzhen

- Service:?EMS/OEM/ODM

- Payment Terms:?T/T,Paypal,WU etc.

- Layer:?2

- Base Material:?Polyimide

- Copper Thickness:?1oz

- Board Thickness:?0.23mm

- Solder Mask Color:?Yellow cover film

- Silkscreen Color:?White

- Surface Finishing:?Immersion Gold

- Test Way:?100% E-Test

- Standard:?IPC-Class2/Class 3

PRODUCT DETAIL

Our production capacity

| PCB Item | Manufacture Capacity |

| ? ?Layer Counts | ? ?1–20L |

| ? ?Base Material | ? ?FR4,High-TG FR4,CEM3,aluminum,High Frequency(Rogers,Taconic,Aron,PTFE,F4B) |

| ? ?Material Thickness(mm) | ? ?0.40, 0.60, 0.80, 1.00, 1.20, 1.50, 1.60, 2.0, 2.4, 3.2 |

| ? ?Max board size(mm) | ? ?1200x400mm |

| ? ?Board Outline Tolerance | ? ?±0.15mm |

| ? ?Board Thickness | ? ?0.4mm–3.2mm |

| ? ?Thickness Tolerance | ? ?±8% |

| ? ?Minimum line/space | ? ?0.1mm |

| ? ?Min Annular Ring | ? ?0.1mm |

| ? ?SMD Pitch | ? ?0.3mm |

| Holes | |

| ? ?Min? Hole Size(mechanical) | ? ?0.2mm |

| ? ?Min Hole Size(laser hole) | ? ?0.1mm |

| ? ?Hole Size Tol (+/-) | ? ?PTH:±0.075mm;NPTH: ±0.05mm |

| ? ?Hole Position Tol | ? ?±0.075mm |

| Plating | |

| ? ?HASL/LF HAL | ? ?2.5um |

| ? ?Immersion Gold | ? ?Nickel? 3-7um? Au:1-5u” |

| ? ?Surface Finish | ? ?HAL,ENIG,Plated Gold,Immersion Gold,OSP |

| ? ?Copper | |

| ? ?Copper Weight | ? ?0.5–6oz |

| Color | |

| ? ?Solder mask | ? ?Green, Blue, Black, White, Yellow, Red, Matt Green, Matt Black, Matt Blue |

| ? ?Silk screen | ? ?White, Black, Blue,Yellow |

| ? ?Acceptable File Format | ? ?Gerber file,Powerpcb,CAD,AUTOCAD,ORCAD,P-CAD,CAM-350,CAM2000 |

| ? ?Certificate | ? ?ROSH,ISO9001,UL |

FPC

| FPC Item | Manufacture Capacity |

| ? ?Layer Counts | ? ?1–10L |

| ? ?Min.?Line?Width | ? ?0.05mm |

| ? ?Min.?Hole?Size | ? ?0.15mm?PTH |

| ? ?Min.?PTH?Hole?Ring | ? ?0.45mm |

| ? ?Min.?Gap?between?Cover?Layer?and?Pad | ? ?0.1mm |

| ? ?Min.?Gap?between?Trace?and?Outline | ? ?0.2mm |

| ? ?Trace?Width?Tolerance | ? ?+/-0.05mm?L≤?25mm |

| ? ?Hole?Size?Tolerance | ? ?+/-0.05mm |

| ? ?Stiffener?and?Outline?Tolerance | ? ?+/-0.25mm |

| ? ?Surface?Treatment | ? ?ENIG,?Gold?Plating,?HAL,?Plating?Pb-Sn |

LEAD?TIME?FOR?PRODUCTION?ORDERS:

| Sample?Lead?time | Mass?production?lead?time | |

| Single?sided?PCB | 1~3 | 4~7 |

| Double?sided?PCB | 2~5 | 7~10 |

| Multilayer?PCB | 7~8 | 10~15 |

| PCB?and?Assembly | 8~15 |

15~20 |

fpc flex pcb with pi stiffener, flexible pcb manufacturer with cheapest price in Shenzhen